| | |

Integrated Electromagnetic flow meter | Split type Electromagnetic flow meter | Insertion type Electromagnetic flow meter |

I . Features:

1. No moving parts, no flow components in pipe, almost no additional pressure loss when measure it, low requirement for straight pipe.

2. Measurement results not link with the velocity distribution, fluid pressure, temperature, density, viscosity and other physical parameters.

3. In the scene, it can modify range on-line according to user's actual needs.

4. High-definition backlit LCD liquid crystal display, it can make reading easier when the direct sunlight or in a dark room. All Chinese menu operation, easy to use, simple operation, easy to understand.

5. It has high reliability with SMD components and surface mount (SMT) circuit.

6. Derive the 16-bit embedded microcontroller processor, a fast calculation speed, high precision, programmable frequency low-frequency rectangular wave excitation; improve the stability of the flow measurement, low power consumption.

7. The whole processing of the digital quantity, strong anti-interference ability, reliable measurement, high accuracy, the flow measurement range of up to 150:1

8.Lower EMI switching power supply, using of the power supply voltage variation range is big, it is good resistance to EMI.

9. It has three integrators inside, reverse the cumulative amount respectively showed positive cumulative integrating quantity and difference, interior has not power off clocks, it can record 16 times power lost time (10 years).

10. With RS485 and RS232, Hart and Modbus digital communication signal output. (Optional)

11. Converter has the function of self-diagnosis alarm output, empty load detection alarm output, the output flow rate on the lower limit alarm, batch control, etc.

12. High voltage electromagnetic flow meter sensor adopts the technology of the PFA and mesh lining, high pressure resistance, resistance to negative pressure, special application of petroleum, chemical industry, etc.

13. The sensor adopts advanced processing technology; make the instrument has a good ability to resist negative pressure.

14. Derive hours record function, total hours for the unit to record the total flow rate, it is suitable for the measuring system. (Optional)

II. PRINCIPLE:

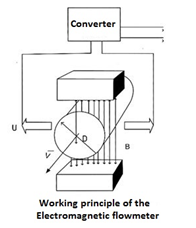

Electromagnetic flow meter measurement principle is based on Faraday's law of electromagnetic induction. Flow meter measurement tube is a lining insulation of permeability alloys short tube. Two electrodes along diameter direction through the wall on the measuring tube. The electrode head and basic flush lining the inner surface. The bi-directional square wave pulse excitation coil excitation will be in a direction perpendicular to the axis measuring tube to produce a magnetic field of magnetic flux density of B work. At this point, if a certain electrical conductivity of the fluid flowing through the measuring tube, then it will cut magnetic induction electromotive force E. Electromotive force E is proportional to the magnetic flux density B, sounding pipe diameter d, and v is the product of the average flow. Electromotive force E (traffic signal) by the detection electrode and through the cable to the converter. After Converter processed flow signal amplification, flow meter can display the fluid flow and output pulse, analog signals, such as current used for flow control and regulation.

E=KBdv

Type: E -- as the electrode signal voltage (v)

B - Magnetic flux density (T)

D - Tube inner diameter measurement (m)

V - Average flow velocity (m/s)

Type K,D is constant, due to the exciting current is constant current, therefore, B is constant, by E = KBdv, volume flow rate Q is proportional to the voltage signal E, namely the volume velocity of the induction signal voltage E and Q into a linear relationship. Therefore, as long as the measured E can determine the flow Q, this is the basic working principle of electromagnetic flowmeter.

By E = KBdv knowable, the medium of the flow temperature, density, pressure, conductivity, liquid-solid two-phase fluid parameters such as composition of liquid-solid ratio does not affect the measurement result. As for flow state should accord with axisymmetric flow (e.g., laminar or turbulent) will not affect the measurement result. So say electromagnetic flowmeter is a kind of volume flowmeter. For manufacturers and users, as long as the actual calibration with ordinary water can be measured after any other conductive fluid volume flow, without any correction. This is a prominent advantages of electromagnetic flowmeter, a don't have any other flowmeter. The measuring tube without activity and choke components, so almost no pressure loss, and have high reliability.

III . Application

Due to electromagnetic flowmeter has its unique advantages, thus it is widely used in chemical fiber, food, papermaking, sugar-making, mining and metallurgy, water supply and drainage, environmental protection, water conservancy and hydropower, industrial area, such as steel, petroleum, pharmaceutical, used to measure all kinds of acid, alkali, salt solution, slurry, pulp, pulp, coal-water slurry, corn starch, fiber pulp, syrup, milk of lime, sewage, raw water cooling, water supply and drainage, salt water, hydrogen peroxide, and beer, all kinds of beverage, liquor, green liquid volume flow of conducting liquid medium, etc.

IV. Main technical parameters

1, The series of nominal diameter DN (mm)

Flange type with PTFE lining: DN6~ DN1200

Pipe type with rubber lining: DN40 ~ DN3000

Insertion type: DN100 ~ DN3000, special custom DN32 ~ DN80

2. The structure form

Integrated type, Split type, Immersion type, Explosion type.

3. Sensor connection way

Flange type, Insertion type, Clamp on type, Healthy type, Diving type

4. Flow direction

Positive and reverse, net flows

Range rate: 150:1

Repeatability error: ±0.1% measurement value.

5. Accuracy grade

Flange type, Clamp on type, Healthy type: ±0.5%, ±0.2% or ±0.3% (Optional)

Insertion type: velocity of 0.5 m/s or less, ±1.5%;Full scale velocity of > 1 m/s, ±1.0%

Diving type: ±1.0%

6. Protection grade

IP65, IP67, IP68 (optional)

7. Medium temperature:

Neoprene/polyurethane rubber lining: - 40 ~ + 70 ℃

PTFE / F46 lining: - 30 ~ + 180 ℃

Insertion type: - 30 ~ + 80 ℃

8. Working Pressure

Pipe type:

DN6~DN300:≤1.6MPa

DN350~DN1000:≤1.0MPa

DN1200~DN2200:≤0.6MPa(special pressure can custom ,highest pressure 42MPa)

Insertion: nominal pressure: 1.6 MPa

9. Electrode type:

Standard type , Scraper type, Replace type.

10. Electrode material

316 l, Harts alloy B, Harts C alloy, titanium, tantalum, platinum - iridium, stainless steel coated with tungsten carbide

11. Lining material

(PTFE), Neoprene, (F46), Polyurethane rubber (wear)

12. Flow measurement range

The flow measurement range corresponds to the velocity range is 0.1 ~ 15 m/s

13. Conductivity range

Flow conductivity ≥5μs/cm, most of the ingredients is water, its conductivity within 200 ~ 800μs/cm, all can choose electromagnetic flow meter to measure the flow rate.

14. The output signal

a. Analog output

The bidirectional two road, all isolation 0 ~ 10 ma / 4 ~ 20 ma

Load resistance: 0 ~ 10 ma, 0 ~ 1.5 K Ω; 4 ~ 20 ma, 0 to 750Ω

b. Frequency output

Forward and reverse flow output, the maximum output frequency can be in 1 ~ 5000 hz inside. With photoelectric isolation bidirectional output transistor open collector. When external power is not more than 35 v, conducting collector current largest 50 ma.

c. Alarm output

Two way alarm output transistor open collector with photoelectric isolation. When external power is not more than 35 v, conducting collector maximum current of 250 ma.

alarm status: fluid atc, excitation of bolt, flow overrun.

d. Pulse output

Forward and reverse flow output, the output frequency limit of up to 5000 cp/S. Pulse equivalent to 0.0001 ~ 1.0 m3 / p. Pulse width is automatically set to 20 ms or square wave. With photoelectric isolation transistor open collector output. When external power is not more than 35 v, conducting collector current largest 50 mA.

15. Communication methods

RS232 or RS485 serial communication interface(Optional), HART communication protocol, FF field bus.

16. Power supply

220 V AC, 50 HZ

24 V DC

Batteries supply, with 2 ~ 5 section 19 AH battery, voltage is 3.6 V (battery replacement), the service life of more than five years. no 4 ~ 20 ma output, with RS485 communication or pulse output.

17. Straight pipe length

pipeline: general requirements: upstream ≥10D, downstream ≥5D;

Special cases can be done: upstream ≥5D, downstream ≥2D

insertion type: upstream ≥15D , downstream ≥10D

18. Explosion proof: EXdIIBT4

19. Environment temperature: -25℃~+60℃

20. Relative humidity: 5%~95%RH

21. Total power consumption

Less than 15 W

22. Product standards

JB/T9248-1999 electromagnetic flow meter